Tetrachloroethylene (PCE) was detected at levels exceeding regulatory screening levels in the first sampling event, but significantly lower during the second. The variability seen in the initial grab and integrated sampling events suggested something more complex than vapor intrusion alone. Continuous indoor air sampling was beneficial in identifying and effectively remediating the contributing sources resulting in reduced investigation costs.

Hargis + Associates, Inc. (H+A) collected grab and integrated indoor air samples during two sampling events eight months apart at an active print shop located within a hazardous waste site in Phoenix, Arizona. PCE was detected at concentrations greater than 2,000 micrograms per cubic meter (µg/m3) during the first event. However, PCE concentrations were significantly lower during the second event, ranging between 50 to 100 µg/m3.

Soil vapor intrusion was originally assumed to be the source of PCE to indoor air in the print shop. PCE was also detected in sub-slab soil gas samples prior to indoor air sampling, suggesting that soil vapor intrusion may have been the source of PCE to indoor air. While indoor air contamination often results from vapor intrusion, concentrations resulting from such sources are typically consistent from event to event. The variability seen in the initial sampling events suggested additional investigation needed to be conducted to further evaluate the nature of the source of PCE to indoor air.

A survey of print shop products indicated that some shop products contained PCE. Additionally, use of the building cooling system varied between the sampling events. Changes in PCE concentrations potentially created by these conditions could not be fully determined using grab and integrated sample results. A continuous air sampling system was brought in to provide a larger dataset in hopes of explaining the variations in PCE concentrations.

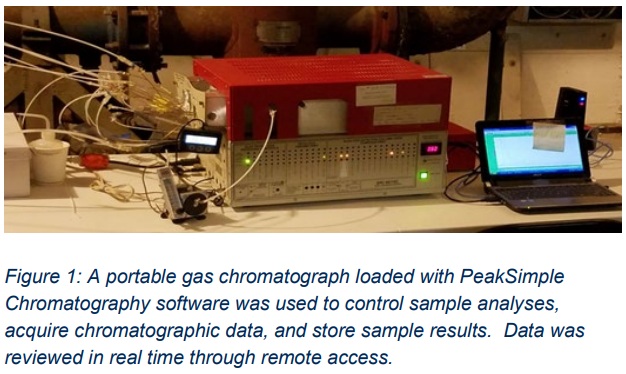

The continuous air sampling system consisted of small diameter tubing connected to the stream-selector valve on a gas chromatograph leading to five sample locations up to 75 feet away. Tubing was placed in production areas where PCE-containing products were used, in office areas where employees congregated, and at an ambient location. Samples were collected through the tubing with a low-flow vacuum pump. Sample analysis time was approximately eight minutes. More than 580 samples were analyzed at each location during a 14-day test.

Results

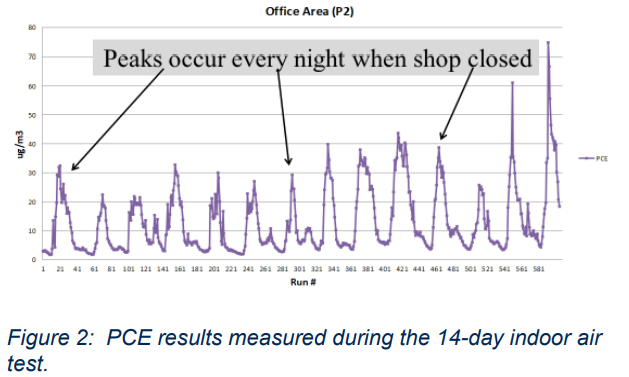

Data from each location were graphed for review and analysis. An example graph is provided below.

Diurnal cycles were clear. PCE peaks were seen each night when the print shop was closed, and the building cooling system was off. The conclusion was that fresh air entering the building when the cooling system was on diluted PCE concentrations during the day. The flow of fresh air stopped once the cooling system was turned off for the night, and PCE concentrations increased.

Graphs of data from production area locations failed to show a correlation between PCE concentrations and the use of PCE-containing products in shop operations –presumably because of the low PCE content in the products or use by employees in fume hoods. This condition and the diurnal cycles seen in the data due variations in cooling system use supported vapor intrusion as the primary source of indoor air PCE.

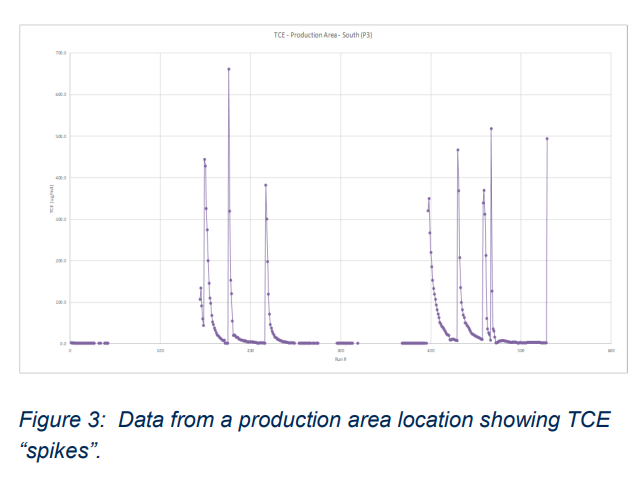

Trichloroethylene (TCE) was observed in one production area but was not present in sub-slab soil gas. With the large dataset provided by continuous sampling, TCE was seen to occur in short, infrequent, high concentration spikes (shown above). This temporal pattern is completely different from the diurnal cycles seen in the PCE data.

Investigation into the source of the spikes determined that a print shop employee was spraying TCE-containing toner infrequently during the test. This issue was effectively mitigated quickly by moving this task outdoors. The nature and source of the TCE would not have been identified and resolved as quickly using grab or integrated air samples – saving time and costs.

Remedy

The results of the continuous sampling resulted in H+A’s installing and operating a soil vapor extraction (SVE) system at the property. Follow-up air and soil gas sampling indicated that the SVE system was effective in removing PCE from soil gas and lowering indoor air concentrations.

Costs

Rates for continuous air sampling systems like the one used on this project typically range from $800 to $2,200 per day. The daily rate is typically dependent on the number of analyses, analytical method, and compounds reported.

The system cost per day is comparable to the cost of three to seven 24-hour canister TO-15 samples, not including labor. The advantage of continuous monitoring is that as many as 140 samples can be analyzed during one day of testing. This could lead to a quicker, more accurate, and less expensive understanding of indoor air conditions at your site.

Closing

Continuous air sampling can add significant value to your indoor air/soil vapor intrusion investigations at a competitive cost. Value through providing multiple data points per day at multiple locations that can be used to develop a more insightful understanding of indoor air conditions at your site. This understanding may expedite the development of effective remedial or mitigative actions and ultimately site closure.

KEY ACCOMPLISHMENTS

• Continuous air sampling identified fluctuations and trends in PCE concentrations not visible in data

from grab and integrated samples

• A portable gas chromatograph with specialty software provided real time data analysis

• Diurnal cycles of PCE concentrations supported vapor intrusion as primary source of indoor air PCE

• Temporal patter of TCE only visible through continuous air sampling allowing speedy identification and mitigation of operation activity causing TCE spikes

• Soil vapor extraction (SVE) system installed

• Follow-up air and soil gas sampling indicated that the SVE system was effective in removing PCE from soil gas and lowering indoor air concentrations