Water is a critical resource for mine operations. Hydrogeologic assessments help mine operators understand potential water supplies available and how to convey that supply to where it’s needed. Thorough characterization of groundwater conditions is particularly important when a groundwater computer model must be developed for mine permitting purposes. Without the right technology and expertise, these groundwater investigations can be more costly and time consuming than necessary.

Fully grouted piezometers can be used to monitor aquifer pressures (water levels) under pre-mining conditions, during aquifer testing, or during pumping or dewatering operations. The use of fully grouted piezometers can be a cost-effective and time-saving method for characterization of aquifer properties in areas of low-permeability rock and fine-grained sediments, such as open pit and underground mines, and to monitor hydraulic heads and pore pressures in bedrock.

This blog presents a review of the design of fully grouted piezometers, applicability to groundwater investigations in complex environments, general methods of installation, advantages and disadvantages of the method, and a review of considerations and difficulties.

Limitation of Traditional Groundwater Monitoring Wells in Groundwater Exploration

In low permeability formations, monitoring of groundwater data using traditional screened and cased groundwater monitoring wells can only detect changes in water levels to within a few hundredths of a foot and generally requires a much longer time period for response and equilibration to occur. Vibrating-wire pressure transducers, on the other hand, can detect water level changes that are orders of magnitude smaller with much more rapid response time.

What is a Fully Grouted Piezometer?

A piezometer is an instrument used to measure underground water pressure. The instrumentation commonly installed in the piezometers is one or more vibrating-wire pressure transducers that are sufficiently sensitive to measure small changes in hydrostatic pressure within the aquifer zones. The pressure changes can then be converted to piezometric head and/or water depths.

The fully grouted piezometer method was first utilized in the early 1960s but not widely utilized until the 1990s. It generally involves installing one or more vibrating-wire pressure transducers in open boreholes at depths of interest prior to injecting grout in the boreholes to surround and fix the transducers in place.

The grout is commonly cement-bentonite grout, although other types of grout mixes could be used. Although counter-intuitive, a properly designed cement-bentonite grout will easily and quickly transmit the pressure change data through the relatively short distance between the transducer and formation. Ideally, the grout should be designed to be less permeable than the surrounding geologic formation to minimize potential reading error.

Advantages of Fully Grouted Piezometer for Groundwater Investigation

The use of fully grouted piezometers is conducive to both rapid download/acquisition of data either on-site or remotely through implementing a telemetry system. Notable advantages of the fully grouted piezometer method over the use of typical screened and cased monitoring wells include:

- Fully grouted piezometers can be installed in exploration coreholes and boreholes that are no longer needed, substantially reducing drilling costs and installation time.

- Transducer and grout installation can be completed quickly.

- Multiple pressure transducers can be installed at different depths in the same borehole, reducing the number of borings required.

- The casing, screen, filter pack and bentonite seals normally used in monitoring wells are not necessary.

- The pressure transducers are very durable and stable and can perform for many years without significant instrument drift.

- Substantial increase in the amount and quality of data collected.

- Much more precise characterization of groundwater conditions than offered by conventional cased and screened monitor wells.

Groundwater Monitoring Program Design and Planning

To design a program for installation of fully grouted piezometers (and other traditional monitoring wells needed), first review the goals and objectives of the investigation. Define the general area of investigation and identify where hydrogeologic data are needed. Identify the areas where hydrogeologic data is sparse or lacking and estimate the number of piezometers and/or wells necessary to adequately cover the area of investigation.

Review all available core/geologic logs, lithologic data, driller logs, geologic maps and cross-sections, and all available hydrogeologic data and reports. Depending on data availability, geophysical surveys may be helpful in delineating the geologic units, structure, and contact depths in the subsurface. From this information, determine the number of pressure transducers needed and the approximate depths for each. If drilling is necessary, these target depths should be reviewed and modified, if necessary, to be consistent with conditions actually encountered by the borehole.

Piezometer Selection

It is critical that the selected transducers be appropriately rated for the anticipated ranges of pressure expected for the selected target depths. Attached communication cables should be long enough to reach from the target depth to several feet above the top of the well or well vault.

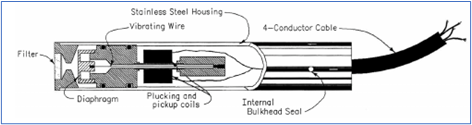

A vibrating-wire pressure transducer is essentially a pressure sensor that houses a thin wire under tension. Changes in the tension of the wire are measured by monitoring resonant frequency which is directly proportional to pressure change. A diagram of a Vibrating Wire Piezometer is shown on Figure 1. A wide range and variety of reliable vibrating-wire pressure transducers are available, as shown in Figure 2.

Figure 2. Vibrating Wire Piezometers (Courtesy of Geokon www.geokon.com/Piezometers)

Drilling and Borehole Preparation

Drilling the borehole for installation of a fully grouted piezometer may or may not be required. If practical, you may decide to use uncased coreholes or boreholes to eliminate or reduce drilling costs. If such drillholes are used, they may need to be flushed out to remove all mud and debris, reamed out to removed sloughed material, or deepened to reach your zone(s) of interest. Borehole diameters of 3 to 6 inches are usually sufficient, depending on the diameter of the transducers, tremie pipe, etc.

If drilling is required, common drilling methods include core drilling, air- or flooded reverse-circulation rotary, although other methods may be more appropriate, depending on conditions expected. Boreholes will generally need to be 3 to 6 inches in diameter, depending on the diameter of the selected equipment (transducers, grouting tremie pipe, etc.) to be installed.

When the borehole(s) are drilled and prepared, geophysical logging should be conducted within the borehole to provide to supplement the lithologic logs to identify geologic formations, strata, structure, contact depths, etc. After the available geologic, lithologic, and geophysical data are reviewed, target depths can be selected for installing the vibrating-wire pressure transducers.

Piezometer Installation

A grout tube or tremie pipe should be selected for inserting or injecting grout into the borehole. It should be sufficiently long to reach the bottom of the borehole. A steel tremie pipe of sufficient thickness to withstand the pressure of the grout is commonly used, although other types of pipe could be used, depending on the depth of installation. The lower 20 to 30 feet of pipe should be perforated to allow grout to flow outward from the pipe into the borehole. The pipe should be installed to the bottom of the borehole. Note that the tremie pipe will remain inside the borehole after installation.

As the tremie pipe is installed, the pressure transducer sensors should be attached to the pipe at the selected depths. The transducer cables should be carefully banded to the tremie pipe, and the cables should be also secured to the pipe at regular intervals from the transducer setting up to land surface. Care should be exercised such that the banding used does not crush or damage the cables or transducers. If multiple transducers are used, care should be exercised to keeping the cables separate from each other so that compromised seals or leaks are not created by the cables. A diagram comparing a fully grouted piezometer and a typical cased and screened monitor well is shown on Figure 3.

Grouting Procedures

The borehole, tremie pipe and transducers should then be pressure-grouted by injecting the grout mixture into the borehole through the tremie pipe. Typically, the grout mixture is cement-bentonite, although other types of grout may be used, provided that its permeability is equal to or lower than the surrounding geologic units. Injecting the grout mix under pressure will fill the borehole from the bottom upward to ensure that bridging in the grout column does not occur. When installed, the grout column should extend to the top of the borehole.

Pressure-grouting operations should be conducted by a licensed cementing contractor or drilling contractor with proficiency and appropriate equipment needed for such procedures. During installation of the transducers and grout, the pressure transducers should be frequently checked to verify they are operating properly.

Why Choose Fully Grouted Piezometers for Aquifer Characterization?

Groundwater investigations incorporating fully grouted piezometers can be a cost-effective and time-saving approach in areas of low-permeability rock and fine-grained sediments, such as open pit and underground mines. Because multiple transducers can be installed in the same borehole at different depths, drilling and monitoring costs can be substantially reduced, compared to the cost of typical screened and cased monitoring wells. Drilling costs can be reduced by installing the piezometers in pre-existing coreholes or boreholes. Transducer and grout installation can be completed quickly.

Fully grouted piezometers will substantially increase the amount and quality of data obtained and will result in more precise aquifer characterization necessary for development of a reliable groundwater model.

If you are dealing with the challenge of characterizing groundwater conditions in bedrock or other lowpermeability rock, particularly for a new mining operation, contact us. We will work with you to develop a strategy unique to your site conditions, project objectives and groundwater modeling requirements.

About the Author

James S. Davis, PG, CHG

Senior Hydrogeologist

Hargis + Associates, Inc.

jdavis@hargis.com

https://www.linkedin.com/in/jim-davis-9144a919/

Mr. Davis is a Senior Hydrogeologist and Project Manager with 42 years of overall experience and more than 35 years in the consulting field. He has worked for many different clients in the mining, industrial and government sectors. His work has included groundwater resource evaluation and assessment, mining hydrogeology including exploration and characterization, environmental permitting and compliance services including agency negotiations, groundwater contamination characterization, groundwater monitoring, and due diligence investigations.