There is often a period during the life cycle of any groundwater remediation project when the finish line appears to be just around the corner, but not yet within reach. Implementing a remedy optimization strategy can get you to closure faster with a lower total project cost.

In this blog, Senior Hydrogeologist Amanda Beam discusses the benefits and important considerations of remedy optimization.

WHAT IS REMEDY OPTIMIZATION?

Optimization of a remedial system is a strategic approach to winning the long game. Remedial optimization comes in many shapes and sizes. Results include improvements to the effectiveness of the remedy, cost reduction, reliance on improved technologies (like green technologies, alternative energy, and material efficiency), and expedited site closure. Remedial optimization can be applied at any stage within the remedial process, even near the end of the remedy when long-term monitoring may be required. It is implemented in Federal, State, and private-sector cleanups. Some agencies refer to it as “remediation process optimization” or “RPO”. Remedial optimization should be customized to site-specific conditions. This includes considering the hydrogeologic setting, the contaminants of concern, cleanup goals, and property use.

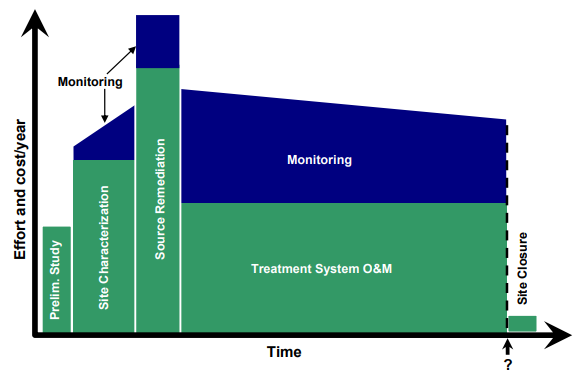

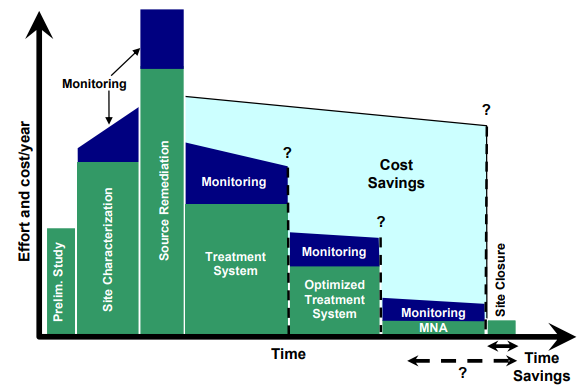

The figures below illustrate the comparison of effort and cost per year over time in typical remedial actions (Figure A) and in remedial actions with RPO (Figure B). Figure B shows a reduction in both cost and time to complete site closure.

A

B

Figures Source: ITRC (Interstate Technology & Regulatory Council). 2004. Remediation Process Optimization: Identifying Opportunities for Enhanced and More Efficient Site Remediation. RPO-1. Washington, D.C.: Interstate Technology & Regulatory Council, Remediation Process Optimization Team. Available on the Internet at http://www.itrcweb.org.

The US EPA Superfund program released a National Strategy to Expand Superfund Optimization Practices from Site Assessment to Site Completion in September 2012. “The Strategy identifies several objectives to achieve verifiably protective site cleanups faster, cleaner, greener and cheaper.” – US EPA

For more information on this strategy click below.

Cleanup Optimization at Superfund Sites | Superfund | US EPA

FOUR BENEFITS OF REMEDY OPTIMIZATION

While there are numerous benefits of remedy optimization for the site owner, this blog will focus on four.

- Short & Long-Term Cost Savings: The sooner the cleanup goals are met, the sooner a site achieves closure by the regulatory agencies. Increasing treatment efficiency can trim years off the remedial timeline, resulting in both cost avoidance and long-term cost savings. Some examples of short-term cost reductions include the automation or simplification of treatment systems, streamlined monitoring (which reduces laboratory and reporting costs), reduced material costs, and decreased energy and disposal costs.

- Reduces Timeframe and Labor: A shorter remedial timeline reduces long-term labor costs for monitoring, project management, and regulatory oversight. The benefit of shortening the remedial timeframe is difficult to quantify when it comes to labor costs since each site is unique and the level of company and/or employee involvement varies. However, the total cost of time spent by employees on remedial related activities may come close to the cost associated with third party consultants and contractors. A reduction or elimination of these labor costs from an expedited site closure is a significant savings.

- Regulatory Agencies View Optimization Favorably: Remedial optimization is quickly gaining popularity and often a win for all interested parties. Currently, US EPA, the Department of Defense (DOD), the Department of Energy (DOE) and several state agencies implement a form of the RPO process. A customized strategy to accomplish the remedial action objectives will determine the overall cost-benefit of your project. Responsible parties that are tasked with a cleanup would benefit from evaluating options for remedy optimization and adapting a strategy that aligns with the common goals of the project during any stage of the project lifecycle. This lends to more congenial relations with the regulatory agencies and stakeholders.

- Reduces Burden of Long-Term Monitoring: Negotiation power increases as concentrations decline and the groundwater plume recedes. Oftentimes, cost associated with routine monitoring can linger and be taxing on a responsible party. Reduction in the size of the monitoring network and the frequency can be renegotiated as progress continues.

CONSIDERATIONS BEFORE IMPLEMENTNG AN OPTIMIZATION STRATEGY

Keep in mind that the more time invested to fully characterize a site and plan ahead, the fewer surprises which may result in cleanup delays down the road. It is good practice to assess the efficiency of the system often and design a strategy that is easily adaptable to the changing conditions typically faced throughout the life cycle of the remediation. Before jumping into an optimization strategy, consider these factors.

- Greater upfront investment is required. Optimization requires a thorough understanding of the site and the environmental conditions before evaluating how best to increase efficiency and shorten the remedial timeline. A detailed conceptual site model is the foundation of every good remedial strategy. Wherever your project is in the remediation life cycle, additional data may be needed to refine or expand the conceptual site model and evaluate remedial technologies to determine the best fit for the site. This requires additional resources which may include labor, contractor costs, exploratory investigations, laboratory, and management costs. Preparing or refining a site conceptual model is also time consuming. The key to creating a high-quality site conceptual model is finding an experienced team of consultants specialized in hydrogeology and environmental remediation. From there, applied engineering is required to evaluate different remedial technologies and potential for reduction of cost and improved performance.

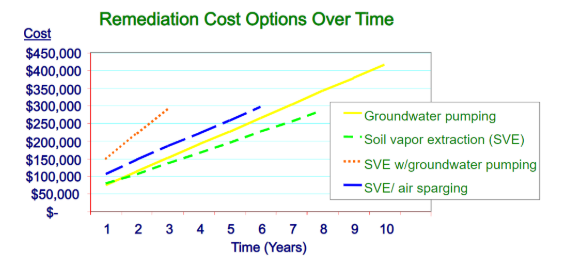

- Cost-benefit analysis is critical. Conducting a comparison of costs helps companies determine how strongly optimization of current remedial systems may benefit their company. It is also used to weigh the cost and benefits between multiple optimization options. A cost-benefit analysis can be conducted at any stage of the remedy, however, the uncertainty of cost increases with the projection of time. The figure below is an example of a comparison of various remediation technologies and their corresponding cost and remedial timeframes for a hypothetical project.

Figure Source: IRTC Internet-based Training Program. What is Remediation Process Optimization and How Can It Help Me Identify Opportunities for Enhanced and More Efficient Site Remediation? ITRC – Shaping the Future of Regulatory Acceptance – ppt download (slideplayer.com). Accessed 5/216/2021.

Another variable causing uncertainty to the life-cycle cost of the remedy is the regulatory agencies and stakeholders’ acceptance of the approach. It is important to work together to establish an optimization plan early on so that all interested parties make decisions aligned with the success of the plan.

3. New areas of contamination may be discovered. It is common for new areas of contamination to be discovered during exploration, requiring an expansion of the conceptual site model and remedial efforts. This is often concerning for the responsible party, however, primary and secondary source areas need to be identified to effectively treat the contamination. A lingering or partially treated source of contamination can extend the remediation timeline and keep a site from obtaining closure. If left unaddressed, contamination may migrate, cause a greater impact, and result in a larger or more technically challenging cleanup down the road.

NEXT STEPS…

The financial and resource drain of long-standing routine monitoring programs and regulatory directives can take a financial toll on any company. By accelerating the remedial timeline, there is potential for significant long-term savings when focusing more resources on the remedy in the short-term. The ultimate goal is achieving site closure sooner than if the remedy remained status quo.

If you have a remediation project underway and are ready to consider optimization, let’s connect. I would be happy to evaluate your project, conduct a cost-benefit analysis for remedial optimization options, and provide a site-specific strategy to increase remedial efficiency. I am committed to help guide my clients through the regulatory process with ease and efficiency.

ABOUT THE AUTHOR

Amanda Beam

Senior Hydrogeologist

Amanda is a Senior Hydrogeologist who has professional experience in hydrogeology and geology since April 2008. Amanda has provided environmental consulting services for soil and groundwater contamination projects throughout the Pacific Northwest, California, and Arizona. Amanda specializes in site characterization and remedial strategy evaluations, bioremediation, optimization of remedial wellfields and wetland, emerging contaminants, and complex project management.

Amanda is no longer with Hargis + Associates, Inc. For questions regarding this blog, please email hargisinfo@hargis.com.