Water resource managers, well field operators, and environmental remediation managers often struggle with the frustration over poor extraction and injection well performance and the unpredictable costs of well rehabilitation or replacement. It doesn’t have to be that way. Establishing a well performance monitoring program benefits project performance and reduces long-term project costs.

In this blog, I will discuss how to assess well performance and implement a successful well performance monitoring program.

INDICATIONS OF POOR PERFORMANCE

Oftentimes, we are approached by well owners and operators who have waited too long to act on poorly performing wells. Occasionally, we find it’s simply too late to rehabilitate and return a well to its original performance or significantly improve well performance to an acceptable level.

Don’t wait to investigate. If you observe trends of increasing electrical costs, declining remediation performance, or diminishing well performance- it’s time dig into the matter.

Declining pumping rates and increasing depth to water are often indicators of fouling of the well screen and filter pack. This typically involves biological or mineral buildup and may require costly well maintenance. With increased depth to water comes increased electrical costs associated with having to lift groundwater from greater depths.

VITAL INFORMATION TO ASSESS PERFORMANCE

Certain data provides key indicators of well performance. Experienced hydrogeologists recognize the warning signs and can provide owners advance notice of potential issues allowing the operator time to take action to mitigate diminishing well performance. Keeping detailed logs of each well and the site history is critical in performance assessment. For extraction wells, your hydrogeologist will look at

- Pumping rates

- Static (non-pumping) water levels

- Dynamic (pumping) water levels

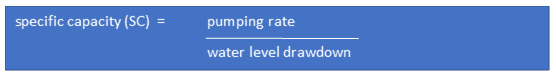

- Specific capacity data

BENEFITS OF A PERFORMANCE MONITORING PROGRAM

Proactive actions at the start of your project such as proper well design, disinfection during construction, and aggressive well development can help extend well performance. Once the well is in operation, establishing a well performance monitoring program can help owners and operators plan for and mitigate the effects of poor well performance on their remediation or water supply projects.

Well performance data including specific capacity (SC), pumping rates, and water levels are the most critical component of the performance monitoring program. A trend graph of the SC over time allows an operator to track well performance and establish a routine well maintenance schedule for each well. A 10 percent (10%) decline in SC is typically an indicator the that the condition of the well may be deteriorating due to fouling of the well screen or other cause. Corrective action should be taken at this point.

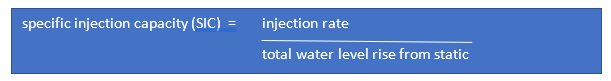

Once performance trends are established, the operator can anticipate and financially prepare for well development maintenance before performance diminishes to an unacceptable level. Well performance monitoring can also be applied to injection wells used for remediation or aquifer recharge using specific injection capacity (SIC) tracked over time. SIC is the injection rate in gallons per minute divided by total water level rise (feet) from static (pre injection level).

CASE STUDY

Extraction and injection well performance monitoring has been used successfully at remediation sites across the United States to help maintain remedy performance and minimize system downtime. A state superfund site in Nevada tracked performance of the extraction well SC and injection wells and recharge trenches SIC as indicators of remediation well field performance. Well performance data were updated on quarterly basis and used to determine well rehabilitation schedules and inform extraction/injection wellfield operational planning. This data included SC, SIC, system pumping rate, and capture zone analysis using water level contour data and Triangular Integrated Network (TIN) analysis.

Soil and Groundwater Investigation and Remediation at a Former Chemical Manufacturing Plant

WELL REHABILITATION AND MAINTENANCE

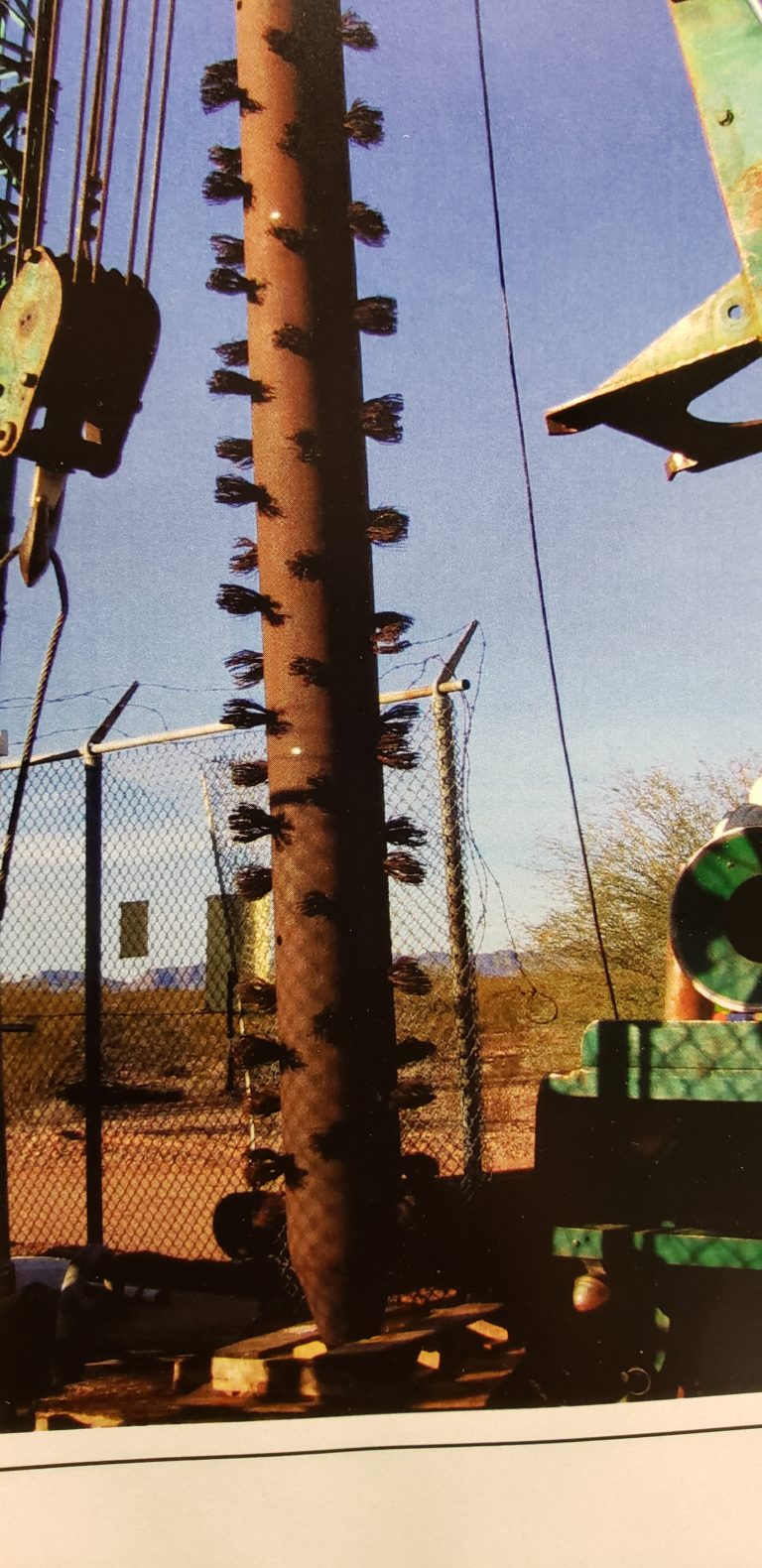

Regular well maintenance and well rehabilitation should include pre-rehab video logging to assess the type and nature of material fouling the well screen so that the operator can develop an effective plan to clean and restore the well to is original performance. A thorough inspection of the well pump and pump column should also be performed to assess for potential corrosion of equipment, presence of mineral or biofilm buildup. If necessary, samples of the buildup material can be sent for laboratory analysis.

Well rehabilitation can include physical cleaning and chemical cleaning. Post-rehab video logging should be performed to visually assess the well screen to determine the effectiveness of the cleaning process. Evaluation of water quality and laboratory analysis of the material fouling the well screen can also help determine what chemicals should be used to clean the well.

Chemical treatment may include disinfection using chlorine or biocide for biologic film issues or acid to address mineral buildup such as calcium carbonate. The delivery method for introducing the chemical into the well is as important as identifying the proper chemical to treat the well.

The operator should work with their hydrogeologist to develop an appropriate and well-specific plan that includes how the selected chemical can be delivered directly to the impacted screen zones of the well (tremie pipe, directed jet, etc.) followed by some form of agitation such as swabbing the well with a surge block or similar tool.

GET STARTED

So, if you don’t have a well-established well performance monitoring plan and/or maintenance schedule get it started today and consider this quote from a recent article in the publication, Water Well Journal:

“If anyone has ever wondered if regular well maintenance or periodic rehabilitation programs were worthwhile investments, consider studies have shown an annual or biannual well maintenance program usually costs between 10%-20% of the cost required for a full-scale rehabilitation procedure. But a typical full-scale rehabilitation process can cost up to 20%-30% of the cost for a new replacement well with the same size and depth.”

Please contact me if you would like to discuss your project needs and learn more about establishing a well performance monitoring program that will help support the long-term goals for your project.

ABOUT THE AUTHOR

Chris Legg, RG

Senior Hydrogeologist

Hargis + Associates

clegg@hargis.com

Chris Legg has been a practicing hydrogeologist for more than 25 years. He has assisted clients on a wide range of environmental remediation projects including state and federal superfund sites, large-scale water resource projects, and numerous well rehabilitation projects. Chris currently serves as a consultant and technical advisor to Arizona Department of Environmental Quality on several of the largest CERCLA sites in the state of Arizona.